The optimal length of freight trains 28/03/22

< Back to listSource: The optimal length of freight trains – Mediarail.be – Rail Europe News (wordpress.com)

The optimal length of freight trains

One of the keys to improving rail freight volumes would be to increase train lengths further. This idea is widespread elsewhere in the world, but in Europe it can only be undertaken under certain technical conditions.

It is again a historical consequence: each network limits the length of freight trains according to its own criteria.

In Spain, most of the sidings on the network have a maximum length of 450 metres, with many sections even shorter.

In Italy, the network is far from uniform. Each railway line has constraints on the maximum mass, which varies according to the type of locomotive used. For an average locomotive, the authorised weights are 1,600 tonnes in the north of Italy, but this drops to 1,500 tonnes if the train is heading for – or leaving – Genoa. On the Tyrrhenian line, the load falls to a maximum of 1,300 tonnes, a low figure which is linked to the characteristics of the Livorno-Rome line. On the Adriatic section it is possible to combine trains up to 1,600 tonnes, while there are restrictions on the Padua-Trieste section at 1,280 tonnes. It becomes a problem when you have to run a train from one end of Italy to the other…

In Germany in 2016, more than 60% of freight trains on the Deutsche Bahn network were less than 600m long. A freight train in 2016 consisted on average of 25-30 wagons, without specifying the size of these wagons. This is a fairly low average.

In France, trains already have an admissible length of 740m. The Perpignan – Luxembourg route was the first to allow longer trains, 850m, bringing the maximum load to 2,400 tonnes instead of 1,800, which is a serious improvement. With two 27000 or 37000 series locomotives, this type of train crosses France in 15 hours at an average speed of 70 km/h.

Some connections between Perpignan, Le Havre, Lille and Luxembourg have already been available for 850m goods trains for several years. The routes are concentrated on the Rhone Valley south of Dijon, the former PLM main line to Paris north of that city, and from Dijon to Metz via Nancy.

Elsewhere in the world

Some comparisons can be made with what is done elsewhere in the world, with all due caution, as the characteristics of the networks differ greatly from those in Europe, particularly in the absence or great weakness of passenger traffic.

The United States has set its freight train limit at 3,658 m because of the limitations of air brake technology, which is used everywhere, including Europe. Australian goods trains are between 1,500 and 1,800 metres long, depending on which part of the rail network they run on.

But it is in the mineral transport category that the greatest records are set. In Brazil, this type of train can be up to 3,200 metres long. In Australia, BHP Billiton’s iron ore is transported in trains of 2,400m with 264 wagons and 4 locomotives.

What are the technical tricks?

The size of a freight train is important because the main interest is obviously economic… and even ecological.

The economic advantage is obvious. The increase in train length obviously has an impact on the carrying capacity. In Spain, the simple fact of going from a length of 540 to 600 metres between the Renault factory in Palencia and the port of Santander has made it possible to transport 20 more cars per train, i.e. 15% more capacity.

There are therefore three main areas to focus on:

- Construction of new engineering structures with gradients more favourable to long trains;

- Extension of sidings and possible adaptation of track circuits in signalling;

- Addition of an optimal number of remote-controlled locomotives to reduce consumption per tonne transported.

Large-scale engineering structures are sometimes ideologically contested because they are designed with growth in mind (as some political groups are calling for degrowth instead). However, these engineering structures increase capacity for several decades and maintain the competitiveness of a climate-friendly mode.

For example, on the Italian side, the work carried out over the Gotthard and Simplon in Switzerland has increased the total capacity of the rail infrastructure to 390 trains per day by 2020, compared with 290 previously. Work on the Brenner in Austria will increase the capacity of the route to 400 freight trains per day.

In France, the Maurienne line is an example of where the limits are quickly reached. This major international route, which passes through Modane, cannot accommodate trains of more than 1,600 tonnes and more than 600 metres in length. The current Mont Cenis tunnel, about 13 km long, is operated under the responsibility of RFI (Rete Ferroviaria Italiana), under a bi-national agreement. Between Chambéry and Saint-Jean de Maurienne, the gradients currently limit the weight of convoys to 1,500 tonnes with a single locomotive. Today, an additional lighter (one more locomotive) is mandatory for trains at St Avre to pass the steep areas between St Jean de Maurienne and Modane. This requires more human resources and makes rail freight uncompetitive.

This sometimes leads to the need to build new structures, with investments that are certainly colossal, but whose investment is spread over almost 100 years of the structure’s life.

The Swiss have chosen this heavy option, with the construction of three giant tunnels throught the Alps. In 2016, AlpTransit Gotthard tested a 1,500-metre-long freight train during the test phase for the Gotthard Base Tunnel, which is possible with a new structure, unlike the old Gotthard Tunnel.

The test train consisted of 76 wagons, divided into flat wagons, wagons with telescopic bonnets and unloaded container wagons. The freight train, weighing 2,216 tonnes, was pulled by three Re620 locomotives positioned at the beginning, middle and end of the train. The ETCS Level 2 signalling and train protection system was also tested several times when such long freight trains were passing through the 57-kilometre Gotthard base tunnel. Among the challenges was the possibility of reversing a freight train of this length out of the tunnel in an emergency.

It remains to be seen, of course, whether this length and weight can be used between Basel and the tunnel, where freight trains have to mix with the large flow of passenger trains.

Sidings

European standards for the length of a freight train are 740 metres and sometimes 835 metres. A 740 metre freight train replaces 52 trucks.

The varying lengths on a country’s network do not encourage the competitiveness of the railways. In Italy, the permitted lengths vary from 480 to 625 metres depending on the line, which makes the process a little more complex when you want to run a train from one end of the country to the other. There is important work to be done to standardise the entire network, which RFI is undertaking.

However, the pressing demand from operators is not to be parked all the time, despite the large flows of passenger trains. Stopping and restarting a heavy freight train every 50km is not very environmentally friendly…

Between 2012 and 2015, an operation with longer freight trains was tested between the Maschen (Hamburg) marshalling yard and Padborg on the Danish border. After the upgrade of the entire 210-kilometre route, freight trains of up to 835 metres in length (40 wagons) ran on this route. In Denmark, 835-metre goods trains have been used for a long time. Previously, the trains arrived at the Padborg border station in two separate batches, whereas now they can run continuously from Hamburg.

In April 2021, the tests went more away, between Hamburg and Malmö in Sweden (via Padborg and Denmark), as part of the project to demonstrate that longer trains pulled by a single locomotive, in this case the EG 3109, were possible over the famous Øresund Bridge between Denmark and Sweden. The locomotive was a Danish 6-axle EG from DB Cargo.

This is an interesting exercise as in Sweden the maximum permitted train length is 730 metres with braking type P, while the infrastructure limits the practical length of trains to 630 metres on many tracks. This means that a Danish 800m train has to be split into two batches at Malmö to continue into Sweden.

How to convert the whole network?

The problem is always financial and depends largely on the investment policies of each country. Converting the entire European network to 750 or 835m is an illusion. This is one of the reasons why Europe has created specific TEN-T corridors, which are supposed to connect all the major industrial areas of Europe and which allow investments to be concentrated. Six corridors of this trans-European TEN-T network cross Germany, including the most important north-south link between Rotterdam/Antwerp and Genoa, which runs along the Rhine and connects the German economic centres of Rhein-Ruhr and Rhein-Main-Neckar. The advantage of this network is obviously that Europe pays…

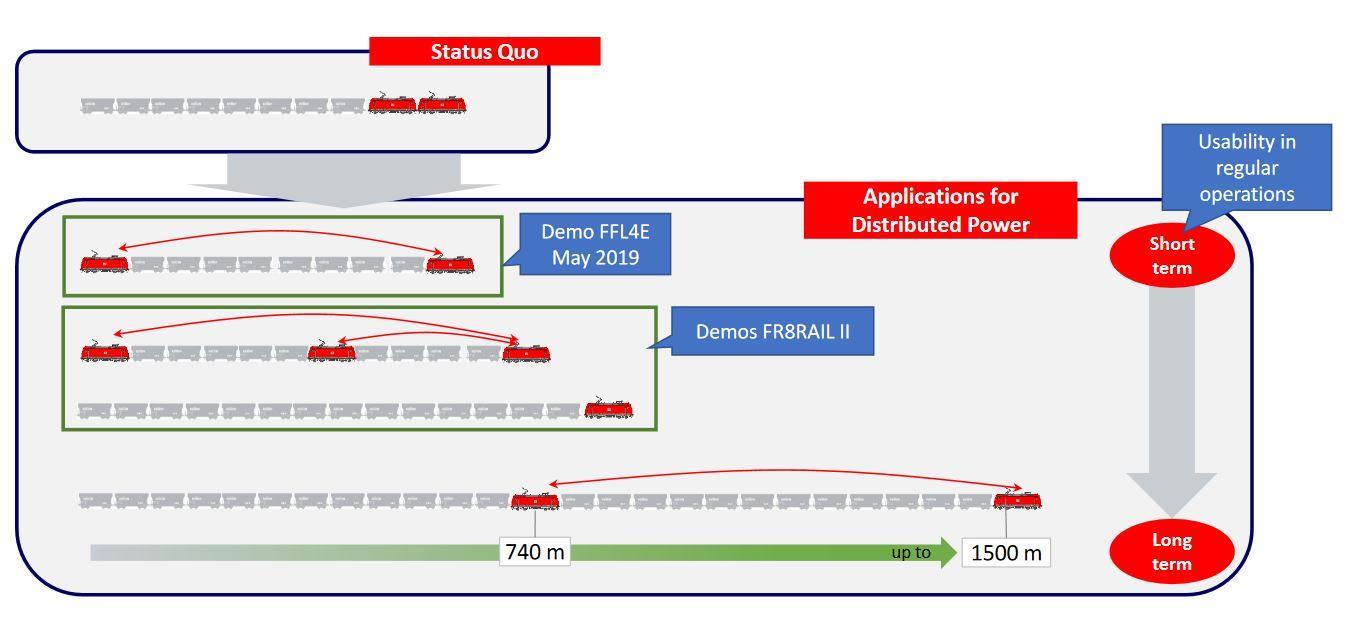

But the length of the sidings is not everything. For longer trains, technical conversions become necessary for a goods train of 1000m length or more, because the driving and braking behaviour also changes with the length and weight of the train. The braking reaction time between the leading locomotive and the last wagon can differ by a few seconds, which is bad for safety and for couplings.

The idea is then to put a locomotive in the middle of the train or at the end of the train. But it is not that simple.

In France, funded by 16 partners including RFF (now SNCF Réseau), Fret SNCF and Europe, the Marathon project experimented in April 2014 with a 1,500-metre long train on an experimental corridor between the Sibelin marshalling yard south of Lyon and the Nîmes Courbessac site. The 1,524-metre train, the longest train in Europe at the time, weighed 4,026 tonnes and had 72 wagons. One of the SNCF’s BB 37000 locomotive, equipped with specific control systems, was placed in the middle of the train.

According to the SNCF, this project would save 5% of energy per tonne transported, and aims to reduce the cost per train-km by 30% compared to current traffic.

In the following years, Fret SNCF and SNCF Réseau launched a second series of tests with 1,000-metre long trains. From October to December 2015, twelve runs were analysed between Somain in the North and Woippy in Moselle. The purpose of these tests was to validate the technical feasibility of 1,000-metre trains. One of the tests consisted of a Somain – Uckange train running for ArcelorMittal, with 67 wagons and a load of 5,410 tonnes over a length of 947 m with 3 machines, 2 of which were at the head of the train, running at 100 km/h.

In 2019 in Germany, a 530m long block train weighing 3,500 tonnes was being tested with « sandwich operation », i.e. two locomotives, one at the front and one at the rear, on a flat line between Hamburg and Bremen.

In 2021, DB Cargo has started trials with two locomotives distributed over the entire length of the train. The DB tests were part of the European research programme « Shift2Rail » and took place on the steeply sloping line between Probstzella and Hochstadt-Marktzeuln near Lichtenfels. The challenge was to solve the issue of remote control connection between the locomotives, one of which is located in the middle of the train (650m in this case), something that is common in the USA.

The TRAXX MS 188 locomotives and two MS 187 units were pulling a train of empty Facns 124, Facns 133 and Rens 677 wagons and loaded Eanos 059 wagons.

A video shows this test:

Initial results have confirmed the feasibility of operating long freight trains with « distributed traction » using LTE (Long-Term Evolution) technology. This is a wireless broadband telecommunications standard that is considered a replacement for the current industry standard GSM-R. LTE is not the latest 5G technology, but a mixture of enhanced 3G and 4G wireless telecommunications.

Energy consumption

The number of locomotives to be placed in a convoy is also an important issue. Apart from the technical question of remote control (reaction to braking, acceleration), it is also a question of measuring what is most optimal in terms of power consumption. In certain circumstances, two locomotives in a long train can reduce the consumption per tonne transported.

was carried out on three trains of different lengths running on the Madrid-Valencia line: a 750m train with two locomotives in multiple units (MUs), a 500m train also hauled in multiple units and a 490m train with one locomotive.

The results showed that with 29,707 kWh/km, the 750m train consumed the most of the three trains with two locomotives. However, the interpretation of the figures differs if one considers the amount of electrical energy needed to transport each net tonne of freight. In this case, the 750m train consumed 0.03201 kWh/tonne-km and emitted 7.902 gCO2/tonne-km, which is less than the 490m train with one locomotive (0.03239 kWh/tonne-km and 7.997 gCO2/tonne-km).

‘This is mainly due to the fact that the consumption induced by the mass (mechanical strength) is spread over more tonnes of freight,‘ the researchers explain. ‘Consumption in freight trains is determined by the mass of the train and not by aerodynamics, as is the case in high-speed trains.‘

Of course, the notion of mass is different from that of length. You can have 1,500 tonnes of light goods requiring a long train, whereas a train with 1,500 tonnes of steel products or bulk goods will probably be relatively shorter.

In conclusion, it can be seen that attempts to lengthen trains toward 800m are beginning to bear fruit. But there is still a lot of work to be done to go beyond that. Between investments in infrastructure (tunnels, longer sidings) and the integrity of the trains, in particular via the future automatic coupling, as well as the remote control of several locomotives on the same train, important choices will have to be made with the establishment of standard norms at European level.

Author: Frédéric de Kemmeter