Intermodal loading units

The advantages of transporting goods in standardised loading units is clear. They simplify handling transhipment (i.e. when using several modes of transport to fulfil a longer distance transport assignment) which reduces costs, use space efficiently, are easier to store and make statistical information easier to record. However, integrating loading units into the transport system is only possible if the carriage, transhipment and storage operations are carried out with loading units whose dimensions are accepted.

Intercontinental Loading Units (ISO containers)

The container came to prominence in the early 1950s (during the Korean War) and today its American origin is reflected in the measurements in feet (ft). Containers start at 20ft long and are made of steel. The advantage of the container is its standardisation and robustness, which are the prerequisites for its stackability.

The ISO container complies with the ISO standard and is the most well-known and successful loading unit for worldwide transport by both maritime vessels and land transport. Around 96% of the containers have a length of 20ft or 40ft. he height can be between 4ft (half-tainer) and 9ft 6in (high-cube container).

The outer dimensions of ISO containers are specified in the DIN ISO 668 standard and permit a tolerance of no more than ± 10mm, setting the internal dimensions as minimum values. The exact dimensions depend on the construction method and the building material. The following table shows the ISO standard dimensions of the most common containers.

European/Continental Intermodal Loading Units

Intermodal Loading units for transport in Europe were developed from the size requirements of railway, road and ocean transport. They conform to the container concept but have been adjusted to continental European requirements with size variations for internal containers, swap bodies and semi-trailers. Those intermodal loading units comply with the EN standards and UIC IRS.

These intermodal loading units (swap bodies, non-ISO containers) must be identified by an ILU-Code and codified before they can be used in intermodal transport by rail.

- European Inland Container: Used within Europe, they have the functionality of ISO containers with the upper corner fittings of standard 2.44m width so standard lifting systems can be used. Overall width is 2.55m, the maximum permitted on road and rail. They are well suited to the European infrastructure as the inner width better suits euro-pallets which, as they are loaded close together, cannot move during transit.

- Swap Bodies: In Europe, swap bodies are usually constructed for loading euro-pallets with a variety of body length depending on application. There are two types of construction, solid walls of wood or metal and those with tarpaulins over a wood or light metal frame. Normally they are equipped with legs so they are free standing at loading ramp height. They are lighter than ISO containers so have better weight carrying capacity.

- Semi-trailers: According to the Article 3(17) of Regulation 2018/858, a ‘semi-trailer’ means a towed vehicle in which the axle, or axles are positioned behind the centre of gravity of the vehicle (when uniformly loaded), and which is equipped with a connecting device permitting horizontal and vertical forces to be transmitted to the towing vehicle. Semi-trailers can be coupled and uncoupled quickly, allowing them to be shunted for loading and to be trunked between depots. If a tractor unit fails, another can replace it without disturbing the cargo. As with any road vehicle, the width of the semi-trailer is 2.55m though refrigerated semi-trailers are allowed to be 2.6m wide to compensate for the internal insulation needed. They are 4.0m high and are generally 13.6m long.

Intermodal wagons

Intermodal wagons – flat- and pocket wagons, as well as specialised rolling motorway wagons – are key assets needed to operate intermodal freight trains. The current European fleet of intermodal rail wagons is owned and/or leased by three types of entities: (1) railway undertakings, (2) CT operators and (3) professional wagon-keepers.

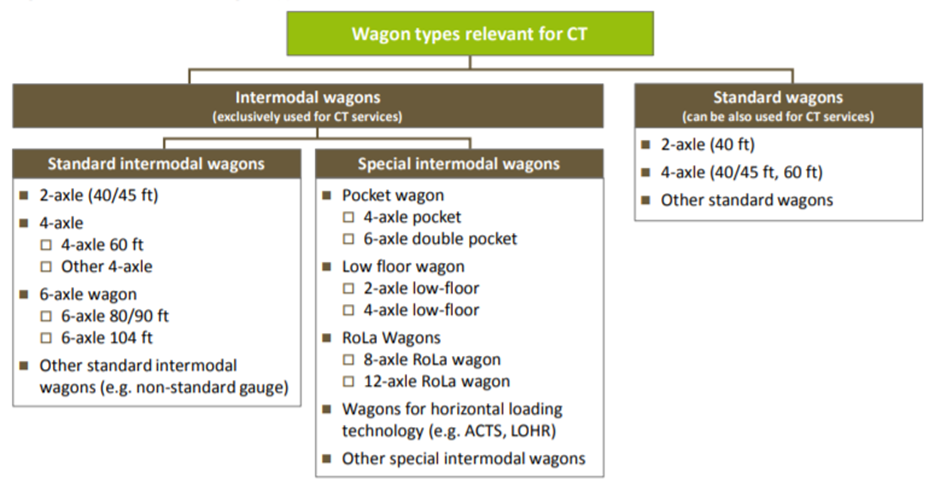

For CT various wagon types exist suitable for different types of loading units and cargo. Basically, the wagon fleet can be differentiated according to:

- Wagons specially designed for CT which are exclusively used for CT services

- Standard rail freight wagons (flat wagons) that can also be used for CT or any other purposes

Intermodal Skeleton Chassis

The initial road leg from the consignor or the final road leg to the consignee can be carried out with or without a “skeleton” trailer. The most common transport system used is a tractor connected to the trailer by the king pin. A modern skeleton trailer can transport swap bodies as well as containers of varying lengths which are fastened to the trailer with twist locks. In case of fowarding a craneable semi-trailer, there is no need for a skeleton trailer.

There are two types of trailers used to transport containers on the road, a “straight trailer” and a “gooseneck” with a step in the frame. Both permit containers widths of up to 2.6m. Gooseneck chassis reduces the overall height of the vehicle and container. This became necessary when high-cube intermodal loading units were introduced to achieve greater loading capacity. The gooseneck step frame semi-trailer overcomes this problem by a recess in the bottom of the container in which the gooseneck plate sits.

Legislation and standards

The CT assets are designed, tested and developed according to the EU legal and standard framework. UIRR, in cooperation with UIC, has performed an analysis of the practices and usages in Combined Transport related to intermodal loading units, wagons and lines (known as CACTUS).

In summary the CT assets are covered by EU Directives, international (ISO norms) and European standards (EN norms) supported by the International Railway Specifications developed by UIC:

- EU Directives 92/106 (CT Directive) and 96/53 (Weights & Dimensions), the Interoperability Directive with reference to TSIs (such on freight wagons).

- EN standards for the European loading units under the coordination of the EN TC 119 (for example EN 13044 for the identification and marking of loading units)

- ISO standards for intercontinental maritime containers

Akos Ersek

Chief Policy Advisor